Jordan Gutierrez Is Carving a Name in the Knife Industry

Interview by Doug Jeffrey

Meet this knife maker who is forging his path to success, by making one custom knife at a time.

ONE: The Path to Black Scale Forge

While working in security, one day a co-worker told me he wanted a knife made from a railroad spike. Coincidentally, I had recently picked one up with the intention of making a knife, so I told him I have one at home and would give it a shot. I did not have the normal tools, however, so I used a BBQ pit, bricks, charcoal, an anvil and a hammer pull on a hatchet.

When I was done, I was disappointed because the knife looked like crap, but I was happy because I enjoyed the entire process. Plus, I knew I would improve.

So, what did my co-worker think? He said, “Give it another shot.”

Despite the outcome, the knife making bug bit me. I fell in love with the entire process. Something just spoke to me, and I knew knife making is what I was meant to do. Since then, I have never stopped. It’s a passion.

TWO: Inside the Company

I created Black Scale Forge four years ago, and I have been doing this full-time for the last 18 months. I work six days a week, six to 12 hours a day. I am self-taught, although some mentors have provided information and advice. Still, no one ever showed me what to do. For me, it has just been trial and error and YouTube “University.”

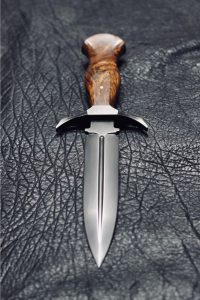

Primarily, I focus on high-end, arty knives because this gives me an artistic release, but I can make something for everyone, including EDC, big choppers and fancy daggers. I can make a wide spectrum of knives, and this is what sets me apart from other custom makers. Many makers choose a style and hammer away at that. I like doing different types of knives.

Since I was a kid, the artistic angle has always appealed to me. When I was younger, I went through multiple hobbies, including bow making, wood engraving and wood burning. There’s just something about the forging process. It is a really cool experience to move steel with just a hammer. It moves just like Play-Doh.

THREE: Challenges and Rewards

Getting exposure for my company is a challenge. The front guys in some companies have big personalities, but I am shy and tend to keep to myself. I have a long way to go, but I am getting better at social media, so the business is growing. Look for me on Facebook and Instagram.

The biggest reward is I work for myself. I don’t have to worry about going to a job that I hate, I get my artistic relief through knife making, and I can take time off for my 12-year-old daughter and 7-year-old son. I also get feedback on social media, and it is always a good feeling when I have made someone else happy with my work.

The dagger blade features 52100 steel and the guard 5160 steel. Both are cold-blued. The handle is ironwood.

FOUR: The Success Formula

While there are different ways to achieve success, I think one of my keys is that I’m always trying to get better. I am never happy, even with my best work. When I look at things I have done, I can sometimes pick them apart. And if I do find something, I make notes so I can make it better next time. That drive to be better is something customers see. This shows them that I care and tells them they are getting my best work.

FIVE: Quick Company Facts

I work in a converted wood barn behind my house. It’s great, but it gets super hot in the summer and super cold in the winter.

The working range for the majority of my knives is $150 to $1,500. My turnaround time is one to two months.

While a customer can order a specific model and request a handle material or a different finish and feel, I don’t take custom orders. A customer can choose details but not design. I used to do custom designs, but it never felt like my work.

SIX: In the Zone

As a knife maker, I have to be in the right zone mentally. On the more complicated builds like daggers, they require a ton of patience. If there is something I am having trouble with, I will stop and come back the next day. That’s when it all makes sense and goes perfectly.

Read about more great knife makers in every issue of Knives Illustrated magazine in print and digital formats!

Subscribe / Back Issues

Subscribe / Back Issues