Dwayne Unger has been a knife maker for only three years, but the 45-year-old Pennsylvania native is already forging a name for himself in the industry.

In this ‘meet the maker’ interview, we take an inside look at Unger‘s quest for excellence.

Where It Began

When I was growing up, I spent a lot of time at my grandparents’ farm. Of course, we had pocket knives, so I’ve always had an interest in knives as tools.

In 2012, I took a bushcraft survival course at the Wilderness Learning Center. As a result, I got more interested in knives and what they could do. I also learned the importance of having a good, quality knife that I could depend on.

Journey of a Knife Maker

I started to collect more knives. I learned about the different styles and handle shapes and began to appreciate what I liked about certain knives. I did everything I could to find that perfect knife. I wondered, if a blade was shaped differently, would it be better than what I could find. This led me to buy more knives. I found things I liked, but the only way to get something just right was to make it myself.

Early Success As a Knife Maker

The first knife I made was out of necessity. With the help of Scott Gossman of Gossman Knives, I made a competition chopper. I made the knife to fit my hand and cutting style. The handle geometry to the blade was good and everything was specialized for me. In 2018, I used this knife on History Channel’s “Forged in Fire: Knife or Death.” In season 1, episode 4, I won.

After that, I built a different competition knife that was lighter with a different handle shape. With that, I won the BladeSports World Championship that year. I knew that I had a knack for knife making because the knives I made required specialized cutting ability and durability.

I also got positive feedback. Scott said he was impressed with how I handled the grinder, and said he hadn’t seen many others with the same skill level so early in the knife-making process. It was humbling, but, like the best custom makers, I felt I had to constantly evolve.

Knife Making Is All about Geometry

To make a quality knife, I’ve learned it’s all about geometry. A good-looking knife with a sharp edge is great; but, if the geometry is wrong, it won’t hold its edge. I learned that with my first knife. Initially, it wouldn’t even cut rope. When I found the perfect geometry, it cut the 2-inch rope, 2x4s and other heavy power cuts without chipping or rolling. Plus, it still had a fine edge to cut paper and other delicate cuts.

Steel Preference

I’m using 80 CRV2, A2 and CPM 154. I use the 80 for chef knives for my best-selling Cadre Cleaver knives. It’s high carbon and with the forced patina I make it look more rustic, as I do not want these knives to look polished and new. A2 is a great steel because it takes a fantastic edge and is easy to maintain in the field. The user can use and abuse them and sharpen them with a river stone. I’m using CPM 154 for kitchen knives because it’s stainless, it has a good edge and is rust-resistant. I’ll eventually expand into additional steels.

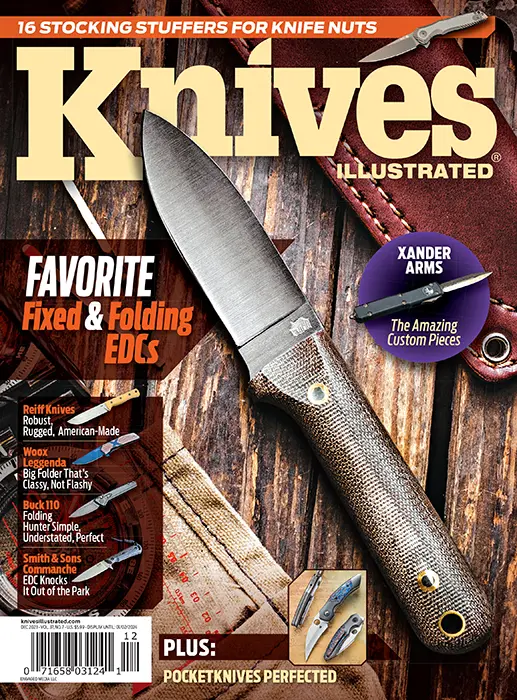

Knife Maker’s Specialty

I’m focused on bushcraft, EDC and kitchen knives. I have, however, made a tactical knife that a good friend designed. I’ll likely add different patterns of custom knives to my future line-up.

I try to make knives that are utilitarian. I build them to be used hard. You’re not going to see high-polished finishes on my knives, and I’m not using elaborate woods yet. My knives are tools. Sometimes the best tool [in your toolbox] is the beat-up hammer because you use it for hard work. Don’t get me wrong though. I want something to look good, feel good and perform well, but you aren’t going to see a super high-polished blade.

Wait Time

I’m not taking too many orders. When I finish a knife, I post it up for sale on Facebook and Instagram.

Subscribe / Back Issues

Subscribe / Back Issues