THE LES ADAMS EOD AUTO AND TBL FLIPPER MODELS SELL FAST. HERE’S WHY.

Sometimes when you walk the floor of a knife show, things catch your eye because they’re flashy, strange, or stand out for some reason. Other times the simplicity and clean lines of a knife catch your eye and tell you that there’s a story behind why those knives are how they are. That’s the case with the work of Les Adams and why I was referred to him to dig a little deeper into his designs.

Background

A lot of you may not have heard of Les Adams, even though he’s been making knives since 1993 and is on the board of directors for the Knifemakers’ Guild. Unlike many makers these days, Les doesn’t have a website, an Instagram account, or anything like that.

If you want one of his knives you need to either find him at one of the knife shows he attends, keep an eye on Arizona Custom Knives (the only dealer he uses), or contact him by e-mail or a phone call.

Most of Les’s work goes to a couple of federal agencies, law enforcement and military units, and individuals lucky enough to discover his work. While Les has made all sorts of knives over the years, he mainly focuses on tactical blades these days.

Les’s background is somewhat unique. He started with a pre-med degree from Penn State University, which I won’t hold against him even though I’m a University of Pittsburgh guy. From there he went on to study at the Gemological Institute of America and received a GIA Master Gemologist degree because that’s the obvious follow up to pre-med.

Adams knives ship with a belt pouch complete with MOLLE attachments for folks who would like to attach it to their vest or gear, rather than clip it to their pocket.

Not content with Medical Gemology, or whatever that combo creates, Les then entered law enforcement, starting in the Florida Marine Patrol and then transferring to the Miami-Dade Sheriff’s Department in 1980. He did 30 years there with the last 15 of it on the bomb disposal unit.

Les is also a licensed Coast Guard Captain certified on vessels up to 25 tons and spends lot of time on the water in his retirement running a charter service.

Les does all the work on his knives himself in his shop. Everything that he sells is built with his own hands, often on tooling he made himself.

He uses a CNC mill that he designed, built, and programmed, as well as a 12-ton press that he uses to make his own carbon fiber for his scales. Les was unhappy with the density of commercial carbon fiber, so makes his own 30-layer, 12×12-inch sheets himself in his press.

At less than 4 ounces in weight, the flipper is surprisingly light for its size.

If you’re looking to find Les, he typically does three shows a year: the Guild Show in Texas, the Blade Show in Atlanta, and the USN (Usual Suspects Network) show in Las Vegas. He’ll generally bring 10 flippers and 10 autos to each show and usually sells out in under a half hour. If you want an auto, your best bet is to find him at a show or call and make some other arrangement, as he won’t ship those through the mail.

Currently, Les is making two knife models: the EOD, which is an automatic and a flipper. Both knives share common features such as carbon fiber scales, 3.375-inch, 154CM drop-point blades with a high hollow grind, and titanium pocket clips set up for right hand, tip up carry. Most of the parts of the knife beyond the blade, handles, and clip are made from stainless steel and everything is heat treated for durability.

THIN BLUE LINE

The flipper that I received for review is marked TBL, followed by a serial number. This is part of a run of Thin Blue Line folders that Les is doing. If you look between the carbon fiber scales, you will indeed see a thin blue liner between them.

It’s a subtle but nice touch. One of the first things that impressed me about the TBL was the weight. Although it’s a full-sized folder, it weighs less than 4 ounces. It’s surprising when you first pick it up. Despite the feathery weight, you can tell the knife is solid in the hand.

The basic drop-point design on the flipper is a good, all-purpose style suitable to its intended utility role. Adams uses a 3.375-inch blade of 154CM stainless steel on his knives.

Les said that he hates the term flipper, even though that’s technically what his knife is. He says that “flipper” suggests you need to snap your wrist to get the blade to snap out. He prefers to call his a “legal automatic” and he’s not off base with that. His blade glides open on a ball bearing assembly that’s about the size of a quarter.

Most ball bearing assemblies are closer to dime sized. He says that his is both bigger and stronger, and I can say it definitely contributes to a very smooth opening system. If you just glide your finger along the spine of the knife the blade snaps into position instantly. There’s very little effort needed on your part, and it is just about as fast as the auto.

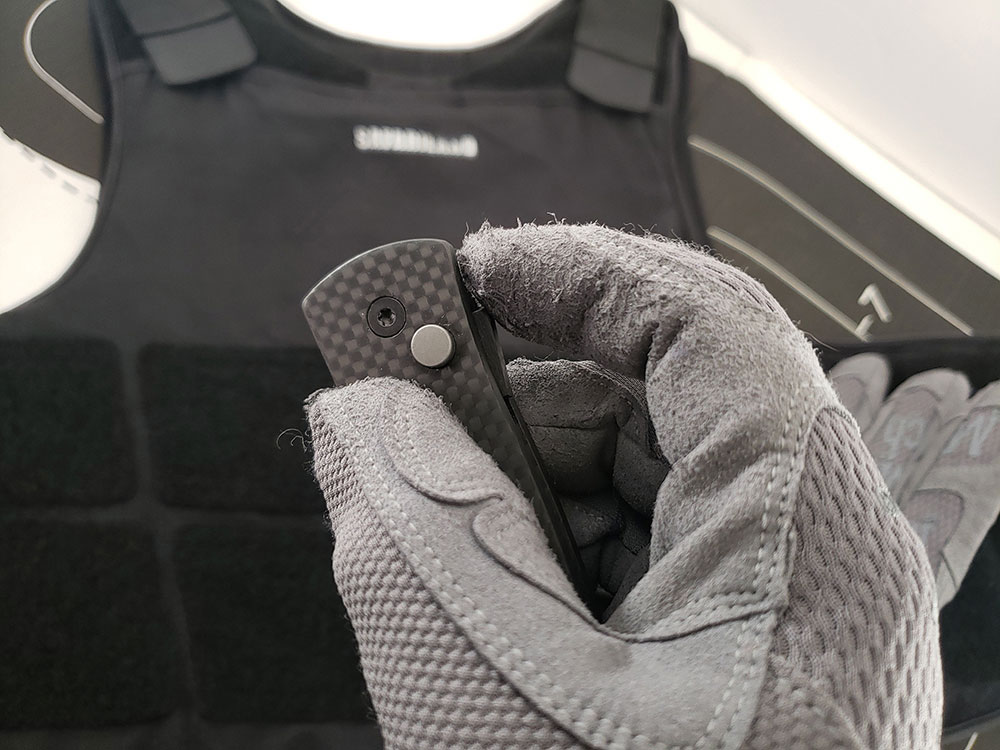

Les Adams’ flipper is designed to be used with gloves as that’s what most of his customers demand. One hand opening and closing are easily accomplished even with gloves on.

Everything in the flipper is modular and repairable. The liner lock spring is made from 1/8-inch of titanium and rides in an enclosed pocket inside the frame that keeps sand and debris out.

Les said this is the thickest liner on the market. It certainly has good engagement as there is no blade play of any sort when the blade is locked open.

The large cutout in the right grip scale gives plenty of room to operate the safety regardless of what the operator is wearing.

To release the lock, you simply press the lock to the left like any other liner lock, but you’ll notice the cutout in the right grip panel that lets you access the lock is rather large. Everything on Les’s knives is made so that you can operate them with gloves on, and this large cutout makes that very easy to do.

Les uses a tungsten carbide ball detent to keep the blade closed and he says that it provides a perfect lockup and won’t wear out like other materials can. I will say, I’ve been nipped by other blades that drift open in the pocket, but this flipper’s blade doesn’t move. I can’t get it to budge even shaking the knife, yet it still glides open smoothly when you hit the flipper lever.

SPECS

TBL Flipper

Blade Length: 3.375 inches

Material of Blade: 154CM stainless steel

Blade Style: Drop point

Overall Length: 8 inches

Closed Length: 4.5 inches

Weight: 3.8 ounces

Handle Material: Carbon fiber

Clip: Titanium, right hand, tip up

Sheath: Black MOLLE-compatible pouch incl

MSRP: $325

EOD AUTOMATIC

The EOD automatic pretty much mimics the flipper in size and materials, but obviously differs in opening and locking systems. Les calls his setup the AOS or Always on Safety. He said that his lock is between 30-40% stronger than most other autos on the market.

“When the blade is open the lock automatically springs back in place so the blade can’t close while you’re using the knife…”

The EOD automatic was designed based upon Les Adams’ experience as a bomb tech and has been steadily scrutinized and tweaked based on feedback from current operators in the field. It is about 8 inches long open. It’s big enough to work with comfortably, but not so big as to take up much room on your gear.

He asked me to give him a call before I tried operating the EOD so he could walk me through it first. Of course, I’m impatient and immediately started messing with it right out of the box. The EOD features a prominent button on the left scale and has a safety tab on the spine of the handle, just below the blade. I thought it fairly intuitive to operate. Simply slide the safety down with your index finger while mashing the fire button with your thumb.

The EOD auto is only 4.5 inches closed and weighs a feathery 3.1 ounces.

The EOD has a strong spring and there’s definitely some kick when you open it, but it seemed fast and positive to use to me. When the blade is open the lock automatically springs back in place so the blade can’t close while you’re using the knife, even if you hit the button by accident. To close it, you repeat the process. Slide the lock down, mash the button, and close the blade. Easy peasy, or so I thought.

To open the EOD, you have to first pull down on the safety with your index finger, then mash the fire button with your thumb. This can be done as one motion with a little practice.

A buddy of mine stopped over when I was first checking out the Adams blades. He also was surprised and impressed with how light they were, and how fast the flipper was. When it got to the auto though, we hit a hitch. I explained to him how the safety worked and on his first try the knife went flying out of his hand.

The EOD auto has thinner walls than the flipper because it doesn’t need to house a liner lock. It still retains great strength and rigidity but shaves off 0.7 ounce over the flipper.

It took a few tries for him to get the technique down and would probably take some practice to be smooth with it. Now, he has a lot of experience with knives, but very little with autos. I’ve been using autos for at least a couple of decades so what to me seemed intuitive wasn’t necessarily. It’s a strong knife with a powerful kick so there may be a learning curve. It’s nothing insurmountable, just something of which you need to be aware.

SPECS

EOD Automatic

Blade Length: 3.375 inches

Blade Material: 154CM stainless steel

Blade Style: Drop point

Overall Length: 8 inches

Closed Length: 4.5 inches

Weight: 3.1 ounces

Handle Material: Carbon fiber

Clip: Titanium, right hand, tip up

Sheath: Black MOLLE-compatible pouch incl.

MSRP: $325

PROFESSIONAL GRADE

Using the Adams knives was a pleasure, not because they’re fancy or flashy, but because they’re very well thought out and precisely executed. They’re lighter than they have a right to be for their size, but they have great lockup and are extremely strong. Although they look blocky, all the sharp edges are knocked off and there’s really nothing to wear on your gear or clothing.

Les Adams fits his knives with a low profile titanium clip that’s inset into the frame. The titanium clip is designed to be low profile so that it doesn’t catch on things when it’s in your pocket.

The slab handles are really designed to be used with gloves, but they’re comfortable enough for basic utility use. I may not want to sit down and do a long wood carving session with them, but that isn’t their intended purpose.

The flipper uses thick carbon fiber scales for strength in lieu of a metal insert to save weight. The author’s sample was part of Adams’ Thin Blue Line series and has a subtle blue liner.

These are tools made by a skilled craftsman who not only has many years of personal experience doing the things these knives are designed to do, but who also gets input from people currently in the field as well.

The simple, blocky lines of the Adam’s blades belie the strength and insight that has gone into their design and construction.

Les says that his designs have evolved over the years based upon user feedback and that’s one of the things that separate them from many other knives on the market. They may be unassuming in appearance, but their weight, their strength and their design make them the choice of professionals.

THE ROOT OF BEING SQUARE

You can see in the photos, and will notice immediately in hand, that the EOD and TBL folders have very square scales. Les breaks the sharp edge, but that’s about it. It’s a departure from what we’re used to seeing these days, but there’s a very good reason for it. A square profile is much less likely to turn in your hand.

Les Adam’s came to this conclusion through all his years working in law enforcement and on the Miami-Dade County Explosive Ordinance Disposal team. It’s also something that his customers on other EOD teams and numerous Federal law enforcement tactical units have requested. One of the things to keep in mind is that folks in these fields operate wearing Nomex gloves most of the time so they need something easy to index and grasp.

I did most of my testing in the Mechanix Wear gloves I use at work and found that Les had done his job well with his auto and flipper designs. Both were easy to operate in gloves and, sure enough, I didn’t have any comfort issues with the slab handles while wearing gloves. Even without gloves, the knives are comfortable enough for basic utility use, such as cutting open boxes, cordage, and all your typical EDC things.

While watching some SHOT Show coverage, I saw an interesting bit of an interview with C.J. Buck of Buck Knives. He was showing an anniversary model of the 112 folder and mentioned how the early knives had fairly square profiles to them. That was because his grandfather, Al Buck, didn’t want the knife to turn in the hand. I thought that was particularly interesting after talking with Les about the profile of his knives and why he did it that way. If it’s good enough for the guys on the three letter EOD and tactical teams, and for Al Buck as well, who am I to question their judgment?

SOURCE

Les Adams

Director, The Knifemakers’ Guild

Email: patadams2226@yahoo.com

Phone: 786-999-3060

Location: Cape Coral, FL

A version of this article first appeared in the June/July2022 print issue of Knives Illustrated.

Subscribe / Back Issues

Subscribe / Back Issues